Base

Step 1: Collecting All Required Parts

3D Printed Parts

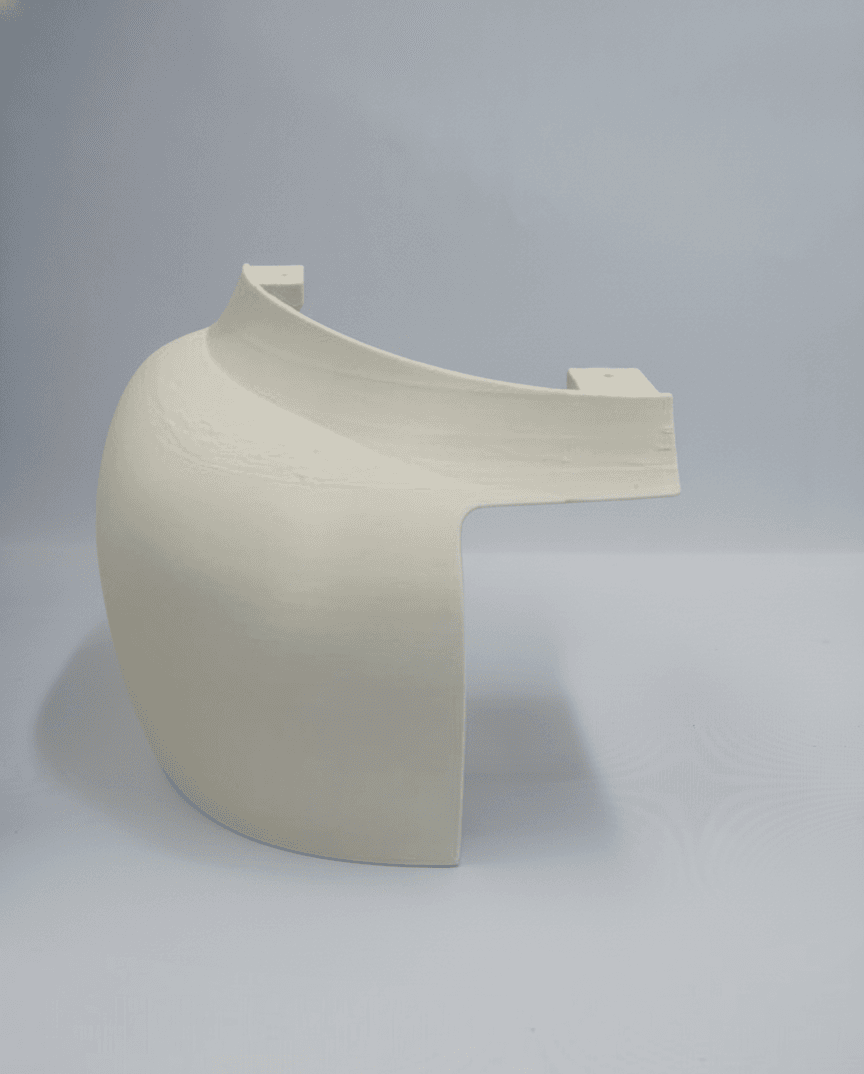

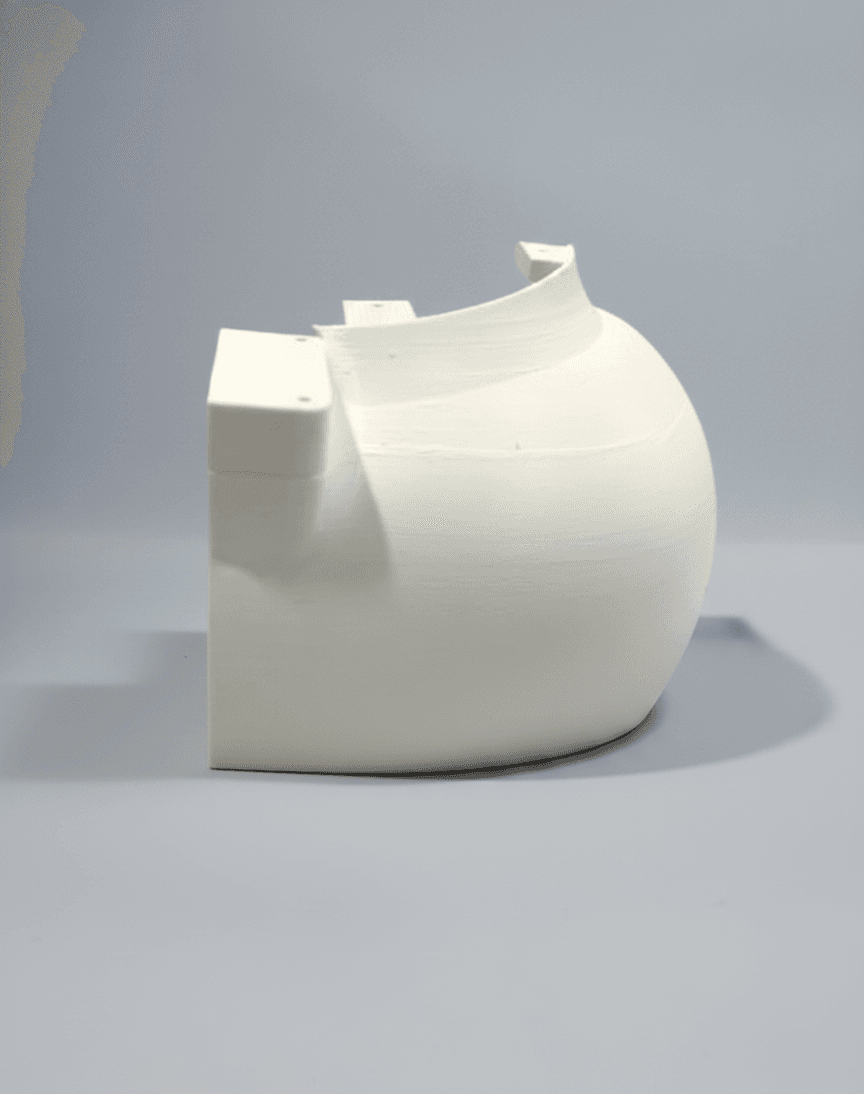

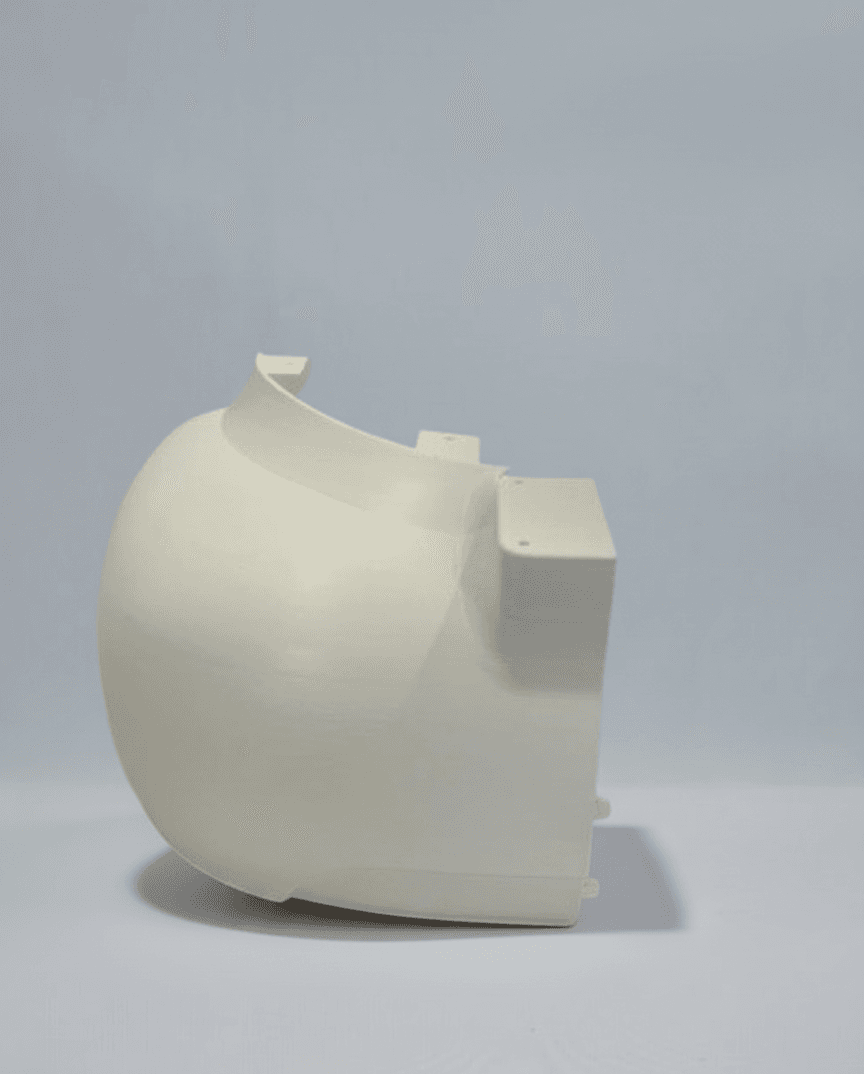

Base Rear Left

Base Rear Right

Base Front Left

Base Front Right

Base Center Cover

Battery Holder

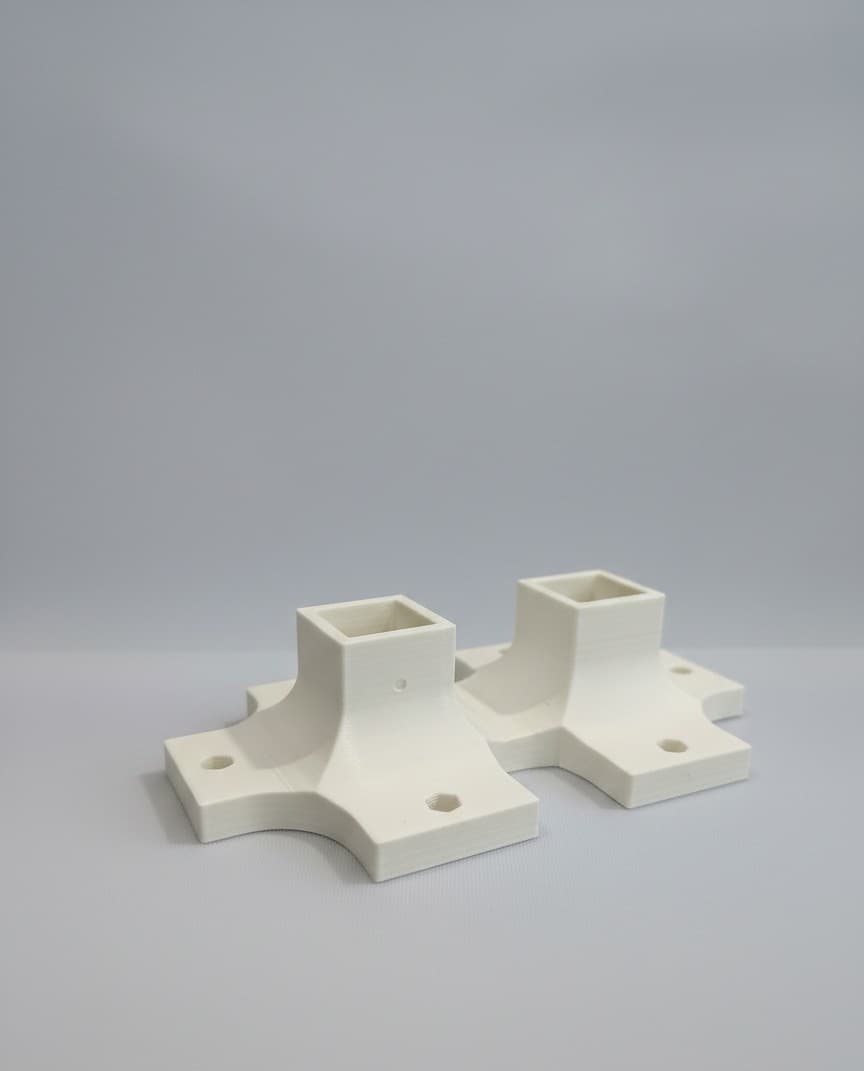

Base Joint

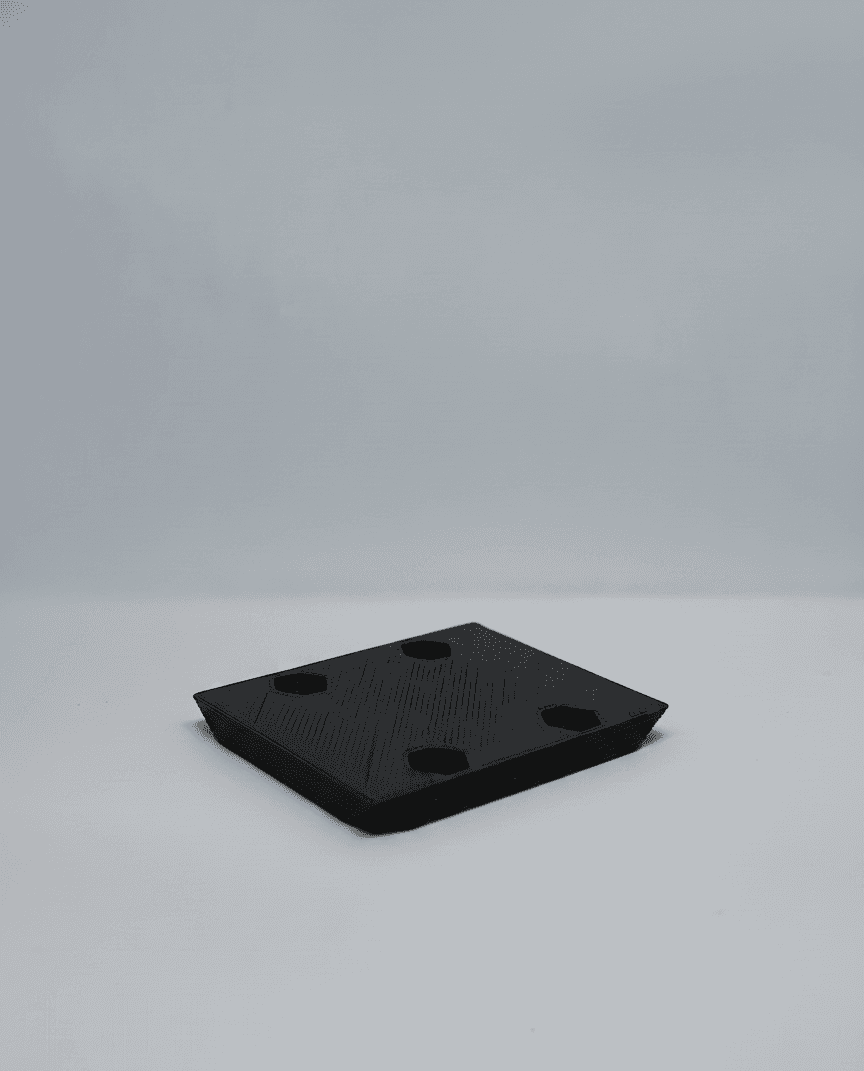

Battery Rail

BCC Acrylic Holder

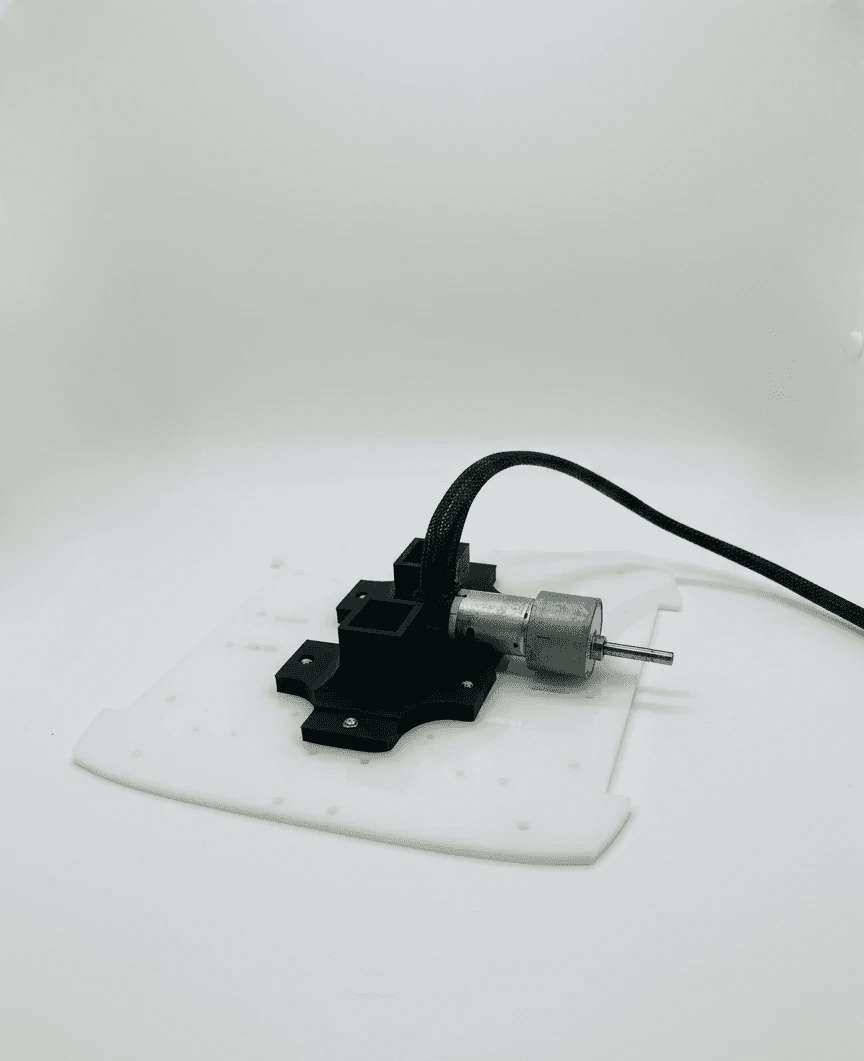

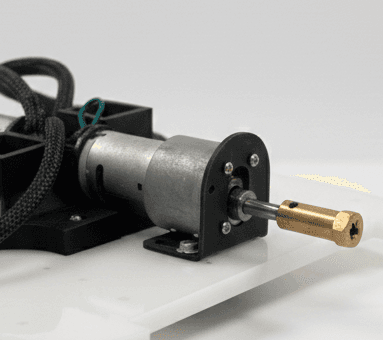

Motor Stabilizer (Image of Motor Stabilizer)

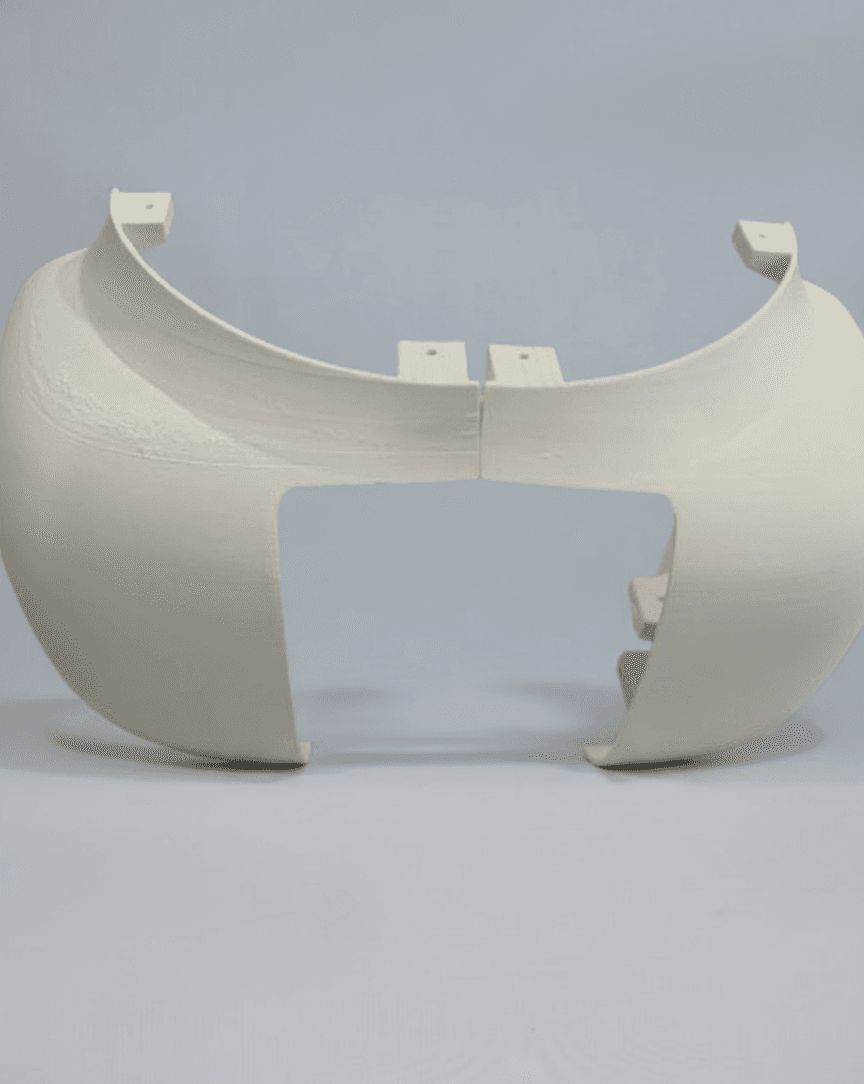

Middle Lower Shell

Middle Center Shell

Middle Top Shell

Body Center Joint

Insert M4 nuts into the designated holes as shown below and glue them if required. Repeat this process for all applicable parts.

(Image of Inserting Nut 1 and 2)

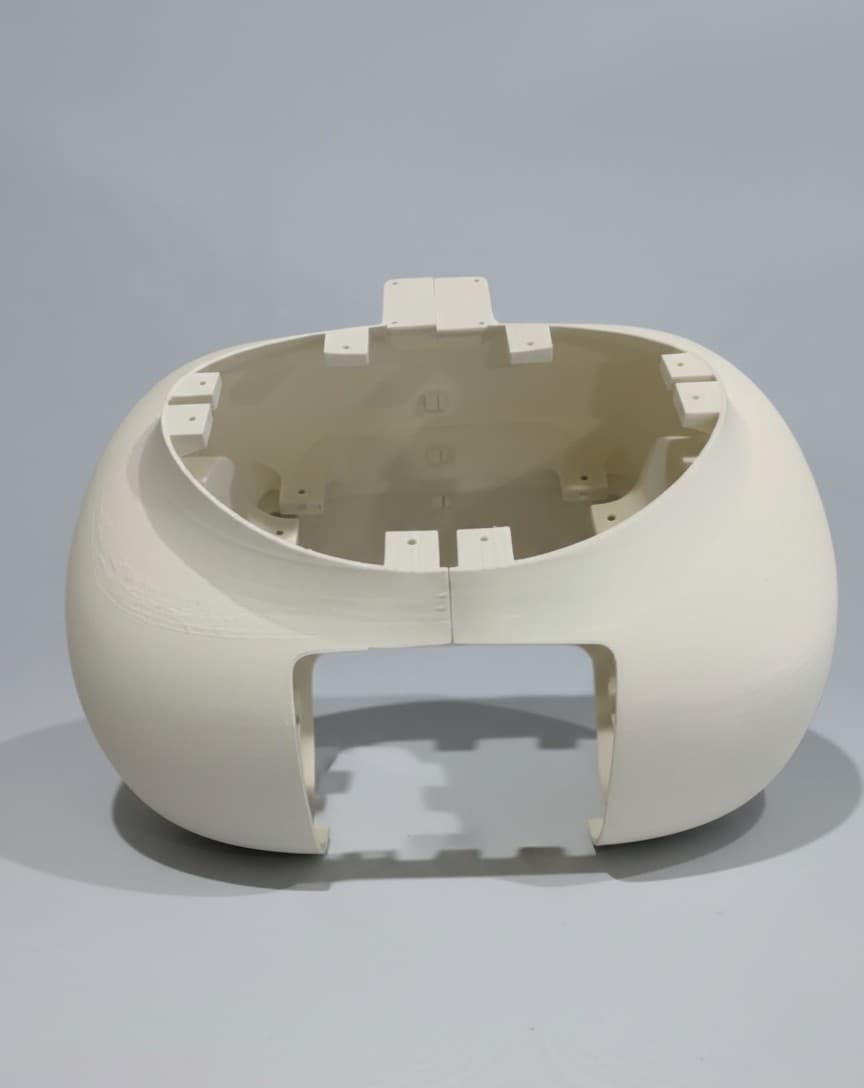

Assemble the parts as shown below to form the base structure.

The assembled base structure should appear as shown below.

Insert 8 x M3 nuts into the base top piece and secure it to the base structure using M3 bolts.

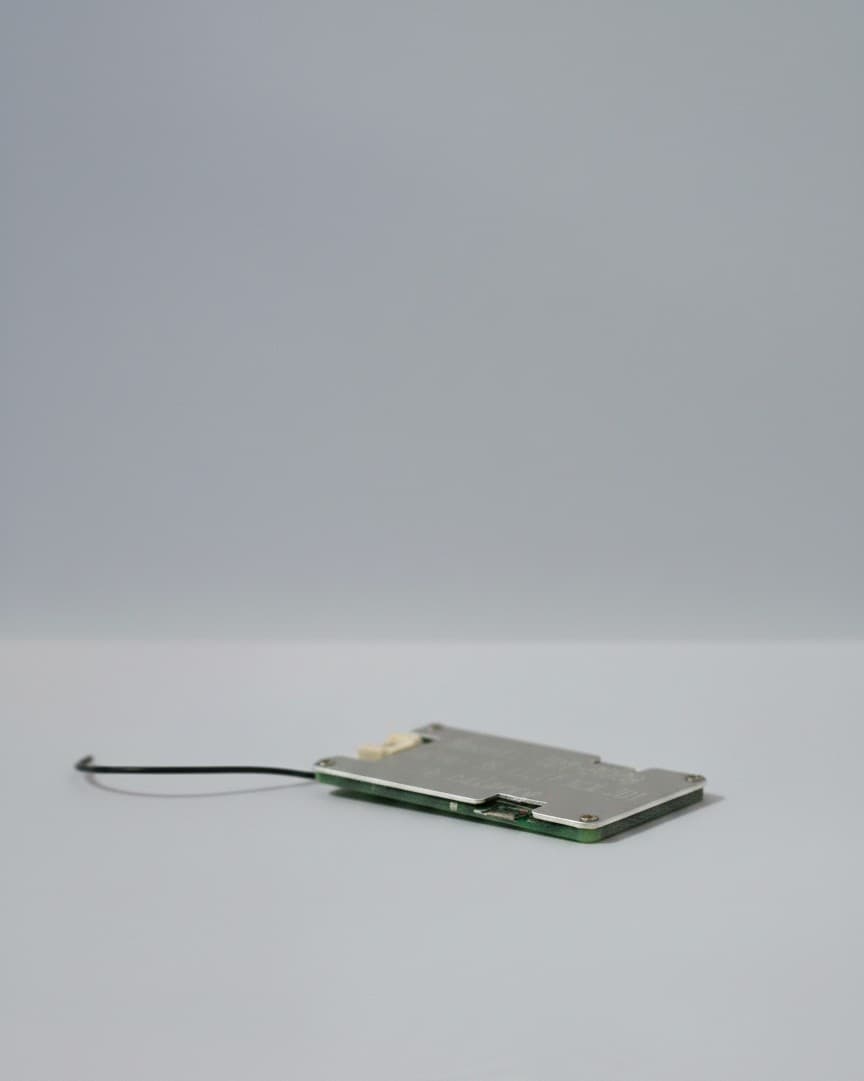

Electronic Parts

- Johnson Motor x 2

- BMS

- RP LiDAR

- Switch

- Battery Connector

- DC Jack (Female)

- Battery

(Image of Switch) (Image of DC Jack Female) (Photo of Battery)

Mechanical Parts

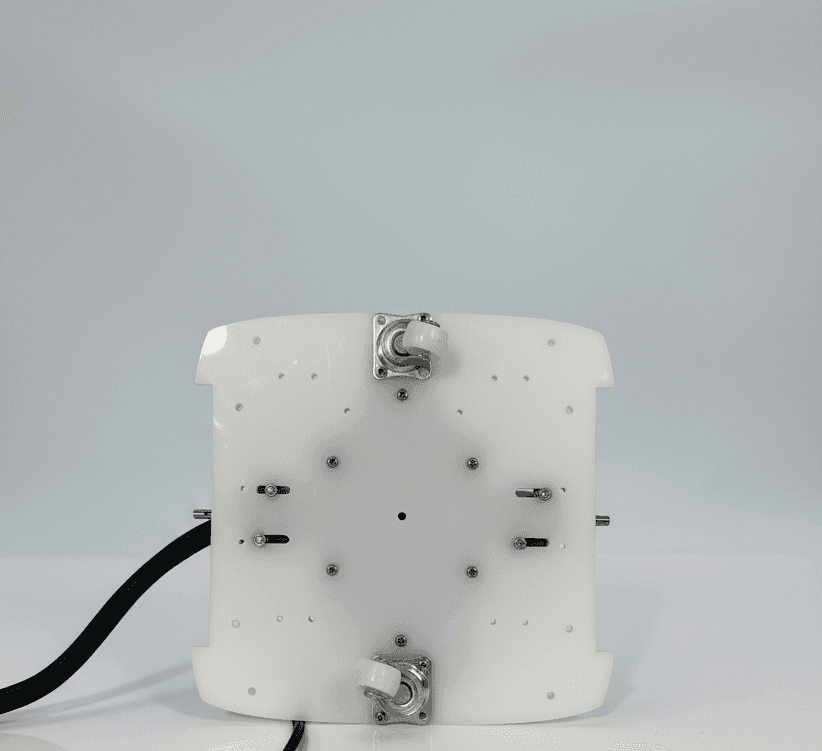

- Base Acrylic

- BCC Acrylic

- Coupler x 2

- Wheel Bracket x 2

- Wheel x 2

- Caster Wheel x 2

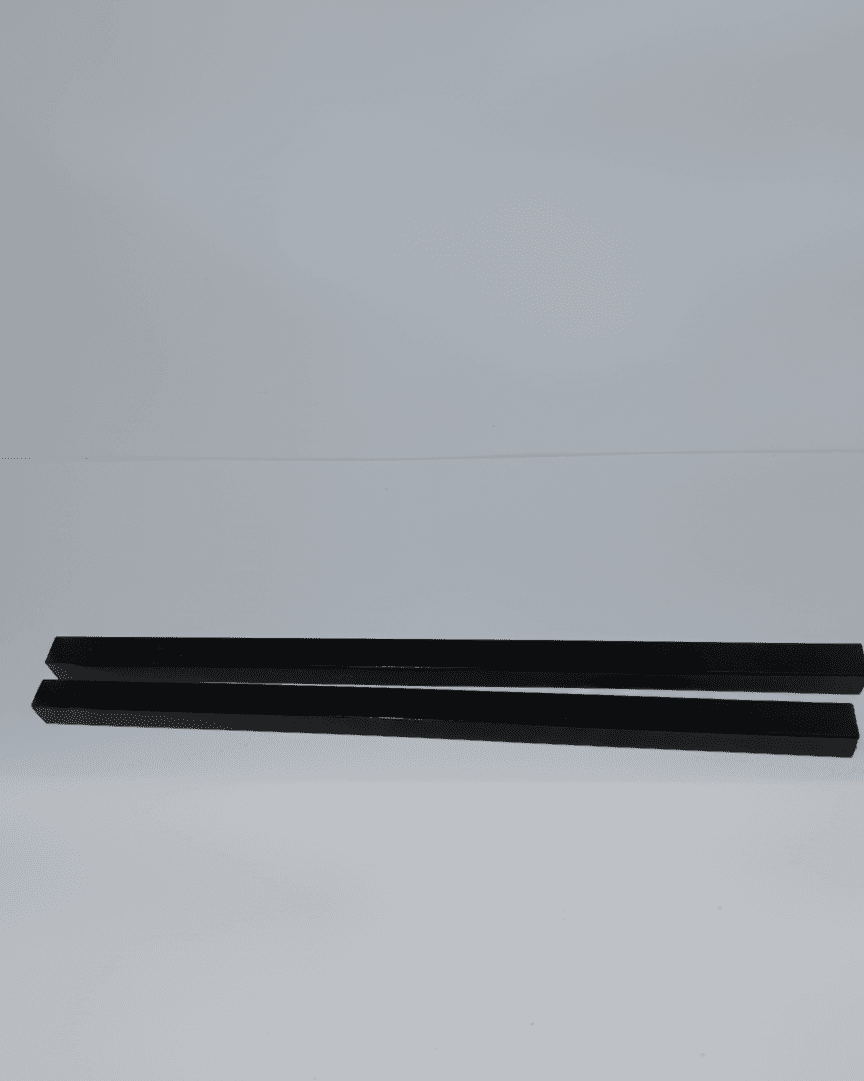

- Aluminium Square Pipe x 2 (51.4 cm, 49.8 cm)

Step 2: Base Body Assembly

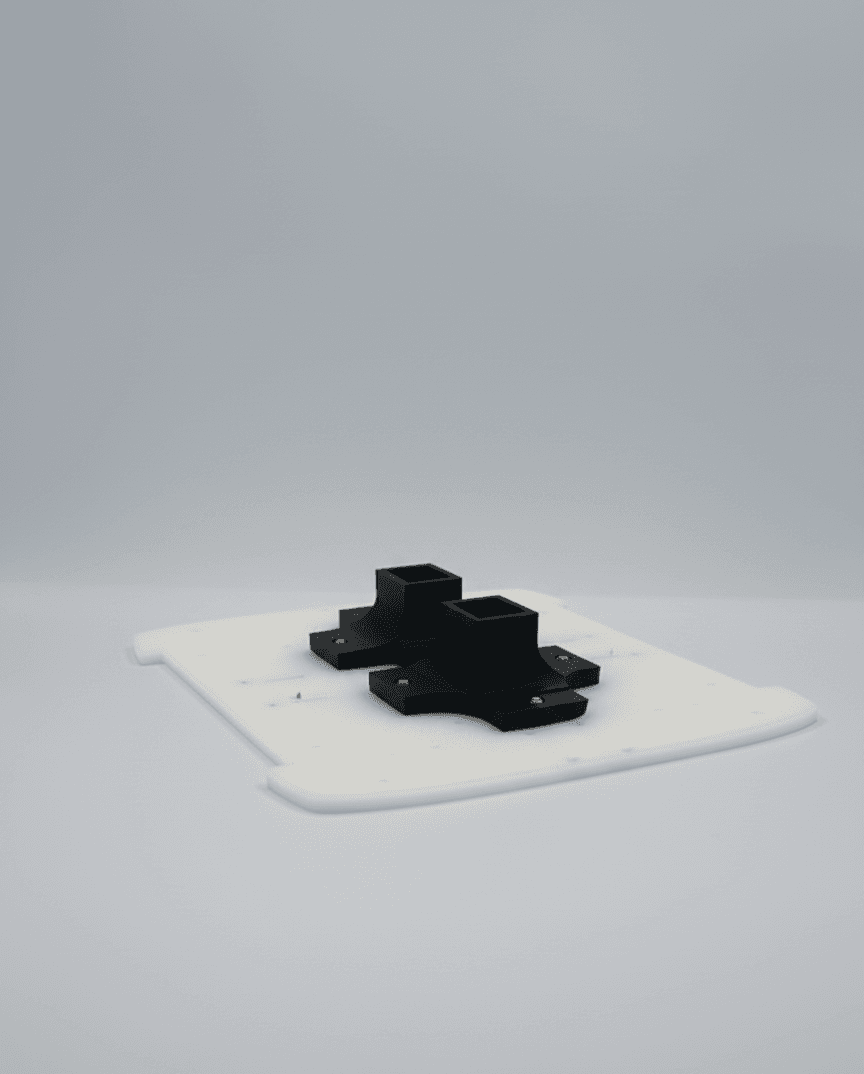

Secure the base joint on the base acrylic using 6 x M4 nuts and M4 bolts.

Mount the Johnson motor on the motor holder and slide it into the base joint.

Install 2 x wheel brackets on the base acrylic using bracket nuts, bolts, and washers.

(Image of Wheel Bracket)

Repeat the same process for the second motor.

Secure the Johnson motors to the brackets using small screws.

(Image of Fixed Wheel Bracket)

Insert 4 x M4 nuts into the battery rail and secure it to the base acrylic along with the caster wheels.

Attach 2 x couplers to the Johnson motors and tighten using an Allen key.

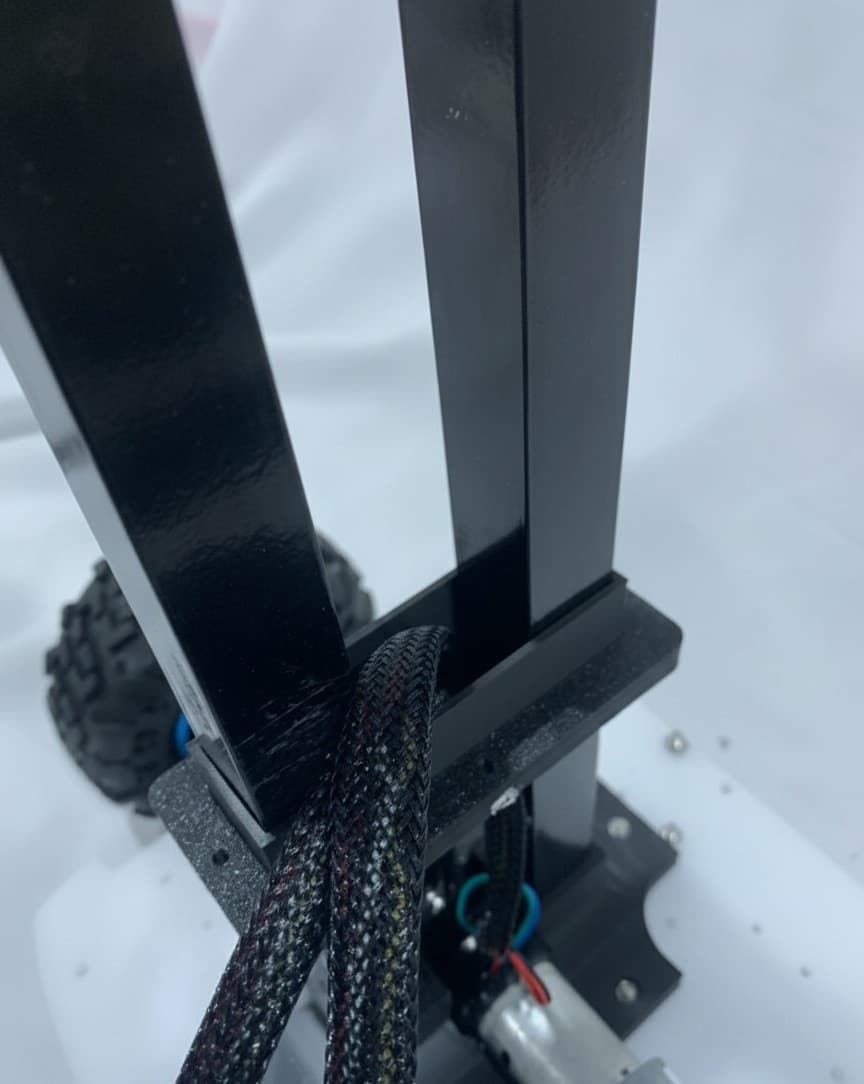

Install one 51.4 cm aluminium square pipe on the front and one 49.8 cm pipe on the rear.

(Image of Fixed Aluminium)

Attach 2 x wheels to the couplers using M4 bolts.

Battery Holder Setup

Install the switch and DC jack in their respective slots and position the BMS inside the battery holder.

Slide the BCC acrylic holder through the aluminium pipe and secure it in place.

Mount the RP LiDAR sensor on the front section.

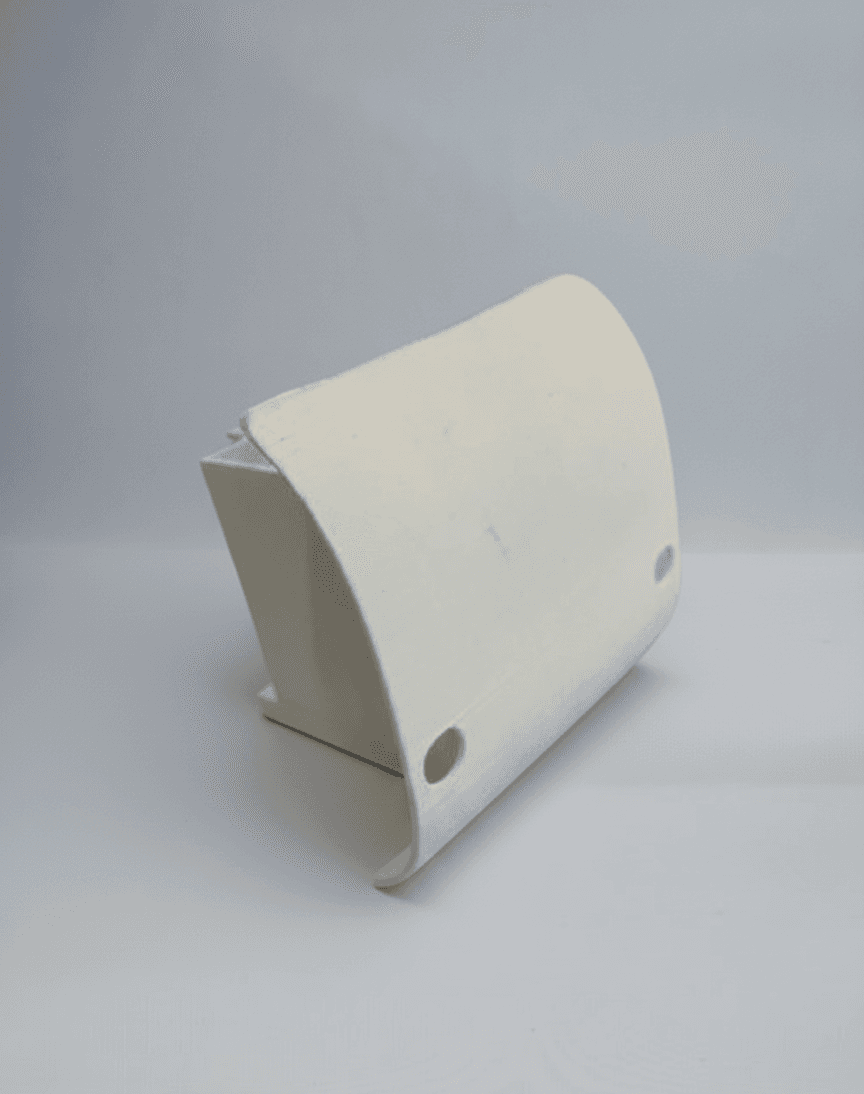

Secure the base portion to the base acrylic using 8 x M4 bolts.

Slide the battery holder through the battery rail.

Lower the BCC acrylic along the aluminium pipes and secure it to the holder using 4 x M3 bolts.

The base assembly is now complete.

Middle Shell Parts

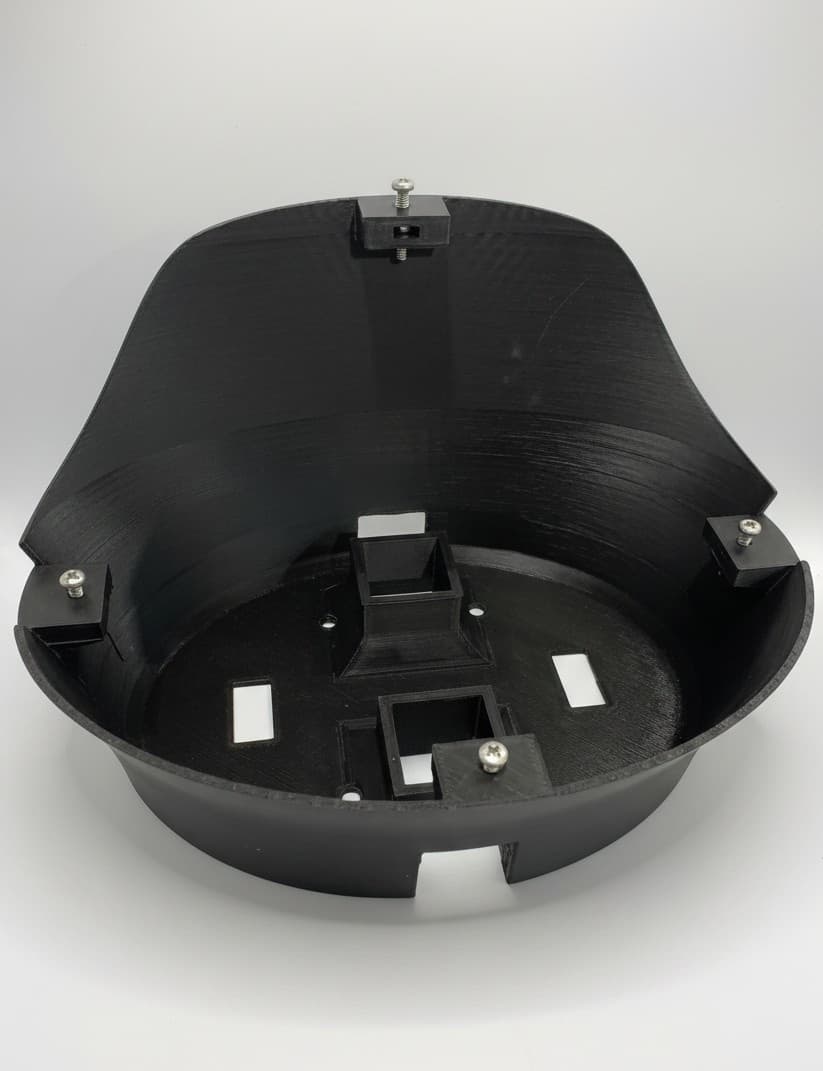

Middle Lower Shell

Middle Center Shell

Middle Top Shell

Body Center Joint

Insert 4 x M3 nuts into the center top and secure them with adhesive.

Step 3: Inner Body Assembly

Secure the body center joint onto the center top using 4 x M4 nuts and bolts. Assemble the middle lower shell, middle upper shell, and center top using 4 x M3 nuts and bolts.

(Image of Fixed Center Joint) (Image of Fixed Center Joint)

Slide the complete middle structure through the aluminium pipes onto the base of the robot. Tighten all fasteners, ensuring proper routing of all wires and cables from the base to the upper body.

The lower body assembly is now complete.